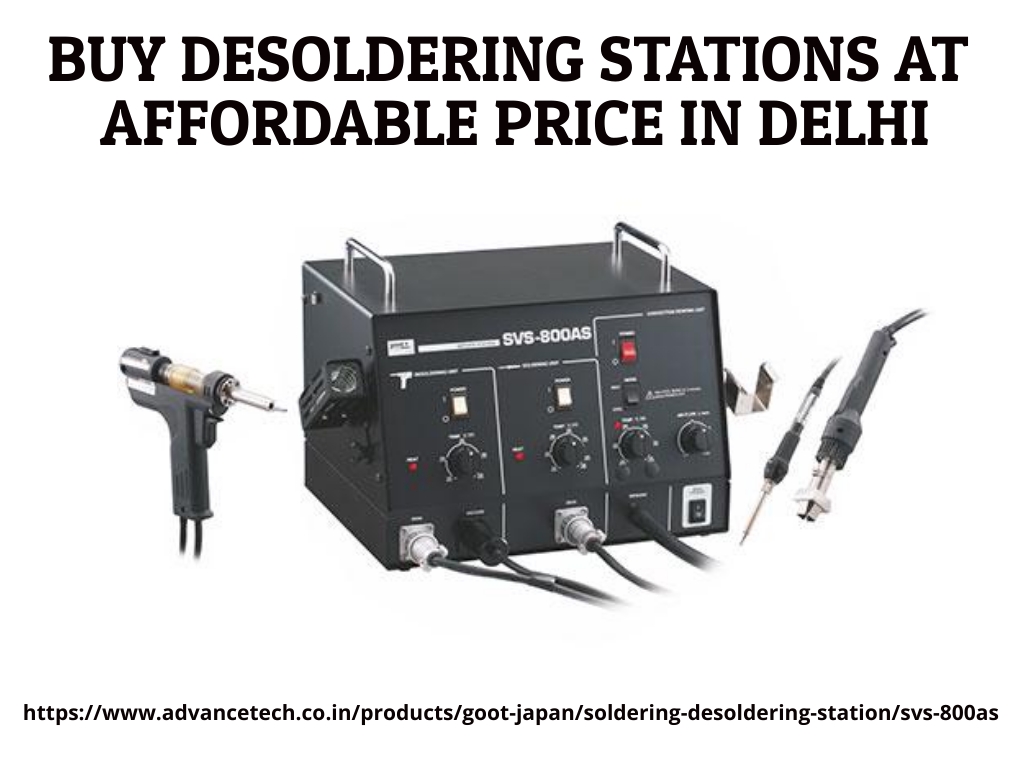

Usage of Desoldering stations vary from really minute straight-forward tasks to heavy-duty applications. Based on the demand and also application, different terminals are readily available, varying in power consumption, temperature range, microcontroller (MCU) based control and also other attributes.

Call Desoldering terminals are the most usual as well as popular sort of Desoldering terminal. These have a built-in power supply unit, which, in most cases, makes certain the galvanic separation between the power circuit and the burner. Voltage on the burner can be readjusted using the power supply device and the heating temperature can be altered appropriately.

Features of Desoldering terminals

Lead-free Desoldering stations are another group that is used to wire lead-free printed motherboard (PCBs). These generally use lead-free solders and also are not always expensive. With several established nations making guidelines favoring lead-free Desoldering, these stations might can be found in handy for future applications. Lead-free Desoldering terminals are specially created for collaborating with lead-free solders, which provide good reliability as well as good solderability.

Although, lead-free stations have their own share of cons such as requirement of extra heat to thaw lead-free solder, which, subsequently, impacts the pointer of the Desoldering iron. Most of the reputed manufacturers enlighten their buyers on perfect usage of lead-free Desoldering stations, which assists them preserve and also extend the life of Desoldering pointers.

Added perks

Desoldering terminals are additionally packaged with various sort of heaters. Ceramic heating systems, induction coil heaters and also combination of heater, sensing unit and Desoldering tip incorporated into one tool are some other variants in Desoldering stations.

Hot-air rework and Desoldering stations are usually made use of for getting rid of components from PCBs and also re-Desoldering brand-new ones. While rework stations are optimal for simple work, Desoldering terminals are mainly used for requiring reworks on PCB boards as well as are relatively more economical.

Hot-air Desoldering terminals are optimum for specialists and also hobbyists because these can be used for pre-heating components prior to getting rid of or can be utilized to reflow SMT elements such as double inline product packaging (DIP), little synopsis incorporated circuits (SOICs), quad flat plans (QFPes) and other ICs.

Desoldering and Desoldering terminals are a have to have for all electronics experts. Nowadays, all stations are electrostatic discharge (ESD) risk-free, Restriction of Hazardous Materials (RoHS) certified as well as digital in nature, the new-age Desoldering terminal supplies digital screen, digital calibration and also password lock functions at an extremely affordable price. Among the recent developments is the induction heating-based hybrid Desoldering station. These terminals utilize the benefits of both modern technologies, IR home heating modern technology and also convection, to highlight the best in Desoldering.

Hot-air stations are featuring built-in turbines for very easy repair work applications and also home heating processes such as diminishing. Brushless wind turbine is included for perfect hot air flow such that warm air temperature is regulated online. Benchtop Desoldering or rework stations have the most accurate temperature controls, ideal thermal healing and added features like programmable timing. Desoldering terminals featured (XX) Technology Desoldering iron ideas. These low-mass pointers provide efficient warm transfer via its silver core.